Pressure vessels are essential components in numerous industries, from chemical processing to oil and gas. A critical element of any pressure vessel is its end closure, commonly known as a “dish head” or “dished end.” The shape of these heads plays a vital role in determining the vessel’s structural integrity, pressure containment capabilities, and manufacturing cost.

This article delves into the primary types of dish heads you’ll encounter:

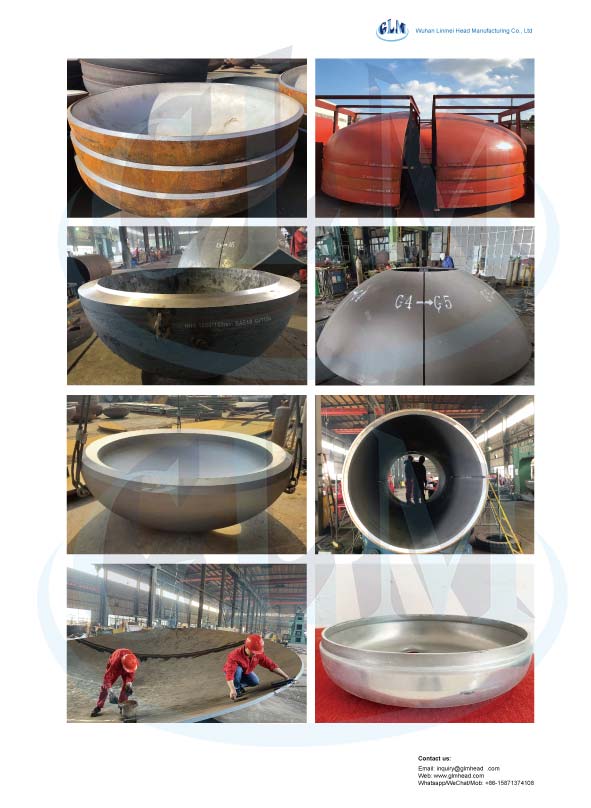

- Hemispherical Heads (Spherical Heads): Revered for their superior pressure resistance, hemispherical heads are half-sphere in shape. Their inherent geometry distributes stress evenly across the surface, making them the top choice for high-pressure applications. While offering the thinnest wall sections for a given pressure, their fabrication often involves multiple welded segments, which can increase overall cost. These are often seen on large spherical tanks used for gas storage due to their exceptional pressure handling.

- Ellipsoidal Heads (or 2:1 Elliptical Heads): These heads feature an elliptical profile, typically with a 2:1 aspect ratio (major axis twice the minor axis). Ellipsoidal heads strike an excellent balance between strength, volume efficiency, and manufacturing economy. They are widely preferred for medium-pressure vessels as they can often be formed from a single piece of material, reducing fabrication complexity. Their smooth curvature minimizes stress concentrations, ensuring reliable performance.

- Torispherical Heads (or Flanged and Dished – F&D Heads): A common and cost-effective choice for moderate-pressure applications, torispherical heads combine a spherical crown with a toroidal knuckle and a straight flanged head section. This design simplifies fabrication, making them a popular option for various storage and process tanks. However, designers must account for potential stress concentrations at the knuckle radius, which may necessitate additional considerations during manufacturing, such as post-forming heat treatment.

Understanding these fundamental dish head types is crucial for selecting the right end closure for any pressure vessel, ensuring both safety and operational efficiency.

Post time: Jun-10-2025